Grabs are essential tools in bulk cargo handling, influencing efficiency, cost, and operational performance. From grains and coal to iron ore and fertilizers, selecting the right grab and optimizing its configuration is key to ensuring smooth and cost-effective loading and discharging operations.

Types of Grabs for Bulk Cargo Handling

Grabs come in various designs tailored for specific cargo types and handling conditions. The most commonly used grabs include:

- Mechanical Grabs – Operated using wires and pulleys, commonly used in shore and ship cranes.

- Hydraulic Grabs – Powered by hydraulic cylinders, offering precision control and enhanced efficiency.

- Clamshell Grabs – Ideal for free-flowing cargoes such as grain, coal, and fertilizers.

- Orange Peel Grabs – Best suited for irregular bulk materials like scrap metal and rocks.

- Motorized Grabs – Self-contained units with built-in power sources for independent operation.

How Grab Capacity is Determined

The capacity of a grab is calculated based on its volume (cubic meters) and the material’s density (tons per cubic meter) using the formula:

For instance, a 10 m³ grab handling coal (density ~0.8 tons/m³) would transport approximately 8 tons per cycle. The efficiency of the grab depends on crane lifting capacity, cycle time, and grab fill factor.

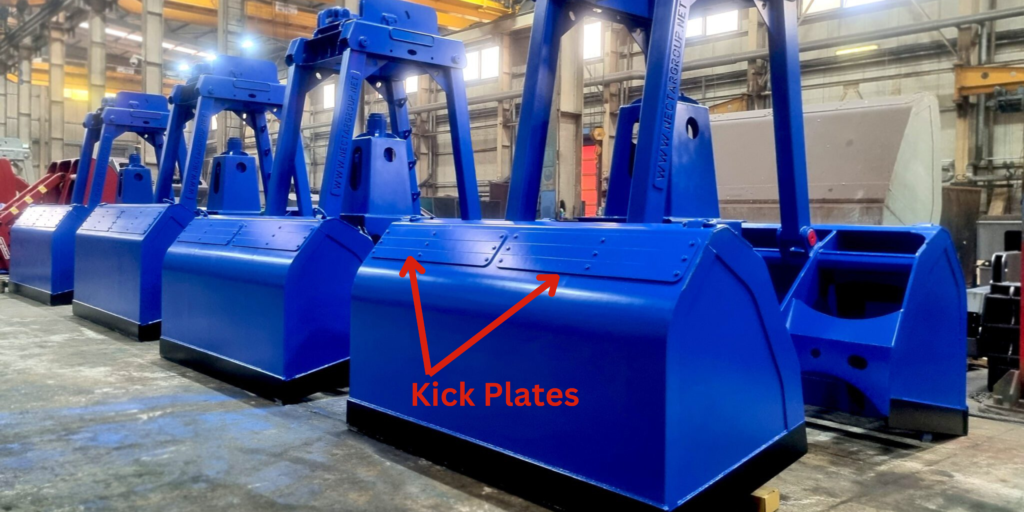

Optimizing Grab Capacity and Weight with Kick Plates

Kick plates, also known as volume reducers, are integral in adjusting grab capacity and weight per lift. They ensure safe and efficient cargo handling, particularly when dealing with varying bulk material densities.

- Purpose of Kick Plates: Kick plates help manage the grab’s internal volume to prevent overloading and ensure compliance with crane lifting capacities.

- Adjustability & Installation: Typically bolted or welded inside the grab, kick plates can be repositioned or removed based on operational needs.

- Operational Benefits: By adjusting the grab volume, kick plates optimize load distribution, reduce spillage, and improve discharge efficiency.

- Material & Durability: Constructed from high-strength steel, kick plates withstand heavy impacts and resist wear, extending the grab’s service life.

- Routine Maintenance: Regular inspections and maintenance are essential to prevent misalignment, damage, or detachment that could disrupt operations.

- Customizable Configurations: Some modern grabs feature modular or removable kick plates, offering flexibility in capacity adjustments to suit different cargo densities and operational scenarios.

Grab Load Calculation Table (With and Without Kick Plates)

The table below provides an estimate of the weight a grab can carry, considering the Safe Working Load (SWL) of a ship crane at 30 metric tons (MT), with a grab volume of 8m³ and a grab weight of 9MT:

| Cargo Density (t/m³) | Load Without Kick Plates (MT) | Adjusted Load With Kick Plates (MT) |

|---|---|---|

| 0.7 | 11.6 | 9.5 |

| 0.8 | 12.4 | 10.2 |

| 1.0 | 14.0 | 11.5 |

| 1.2 | 15.6 | 12.8 |

| 1.5 | 18.0 | 14.5 |

| 1.7 | 19.6 | 15.8 |

Note: The adjusted load accounts for the effect of kick plates reducing the grab’s internal volume, ensuring it remains within the crane’s SWL and operational efficiency limits.

Key Commercial Considerations When Choosing a Grab

Selecting the right grab directly impacts loading/discharging rates, port turnaround times, and overall freight economics. Key factors include:

- Cargo Characteristics: High-density cargoes require smaller grabs to prevent exceeding the crane’s safe working load (SWL).

- Port & Terminal Constraints: Some terminals impose grab size restrictions due to infrastructure limitations.

- Crane Compatibility: The grab should align with crane lifting capacity, outreach, and cycle time for seamless operations.

- Demurrage & Despatch Efficiency: Optimized grab selection can minimize demurrage penalties and maximize despatch earnings.

- Operational Cost Savings: A well-matched grab enhances energy efficiency, reduces mechanical strain, and extends equipment longevity.

Conclusion

Grabs are vital for bulk cargo logistics, and their performance directly influences commercial efficiency and port productivity. Understanding grab capacity, utilizing kick plates effectively, and selecting the appropriate grab type can enhance operational performance, reduce costs, and improve turnaround times. As technology advances, innovative grab designs and optimization techniques will continue to reshape the industry, paving the way for more efficient cargo-handling solutions.

For expert guidance on selecting and optimizing grabs for bulk-handling operations, contact us today!