Efficient voyage planning and cargo optimization are crucial in the shipping industry, especially when vessels transit through multiple Load Line zones with varying seasonal restrictions. Understanding how to calculate the maximum permissible load while ensuring compliance with international regulations can help prevent operational inefficiencies, regulatory penalties, and safety risks. This guide provides an in-depth analysis of loadability calculations, featuring real-world examples and a case study.

Understanding Load Line Zones

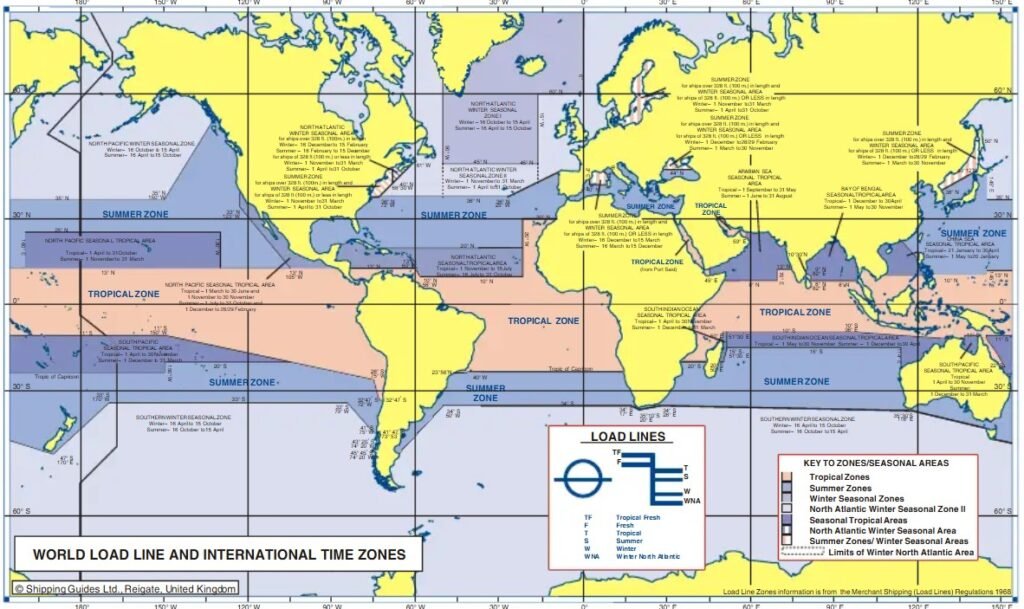

The International Load Line Convention sets regulatory standards to maintain vessel stability and freeboard, ensuring safe navigation through different oceanic regions. The world’s seas are divided into Load Line zones, which fluctuate based on seasonal weather patterns:

| Load Line Zones | Characteristics | Permissible Draft |

|---|---|---|

| Tropical Zone (T) | Calmer waters, highest permissible draft | Maximum draft allowed |

| Summer Zone (S) | Standard reference for load calculations | Standard draft limit |

| Winter Zone (W) | Rougher sea conditions, requiring higher freeboard | Reduced draft allowance |

| Winter North Atlantic (WNA) | Most restrictive, highest freeboard required | Lowest permissible draft |

Key Factors Influencing Maximum Loadability

1. Vessel-Specific Load Line Assignments

Every vessel is assigned Tropical, Summer, Winter, and Winter North Atlantic freeboards by its classification society. The Summer Load Line serves as the benchmark, with adjustments made for other zones.

2. Planned Voyage Route and Load Line Zones Restrictions

If a ship’s voyage crosses multiple Load Line zones, the most restrictive zone will dictate the maximum allowable draft at a given point in the journey.

3. Ballast and Stability Considerations

Compliance with intact stability and damage stability requirements is essential to maintain safety and prevent excessive stresses on the hull during the voyage.

4. Impact of Bunker Consumption and Mid-Voyage Refueling

Bunker fuel management is a critical yet often overlooked factor in loadability optimization. The weight of fuel onboard affects the vessel’s draft, and improper planning can lead to reduced cargo intake or regulatory violations. Key considerations include:

- Fuel weight variations: As bunkers are consumed, vessel displacement decreases, potentially impacting stability and draft compliance.

- Draft fluctuations: A vessel heavily bunkered at departure may exceed allowable draft limits in restrictive zones before consuming sufficient fuel.

- Mid-voyage bunkering strategy: Strategic bunkering at locations with fewer restrictions can optimize cargo intake while maintaining compliance.

For example, if a vessel plans to bunker in a Winter Zone before entering the Winter North Atlantic Zone, it must ensure the additional bunker weight does not exceed draft limitations before reaching its next load line transition.

Practical Example: Loadability Calculation

Consider an Ultramax bulk carrier with the following assigned freeboards:

| Load Line Zones | Freeboard (m) |

| Tropical | 9.00 |

| Summer | 9.20 |

| Winter | 9.50 |

| Winter North Atlantic | 9.80 |

Voyage Route via multiple load line zones:

- Load Port: Santos, Brazil (Tropical Zone)

- Transit: South Atlantic (Summer Zone)

- Transit: North Atlantic (Winter North Atlantic Zone)

- Discharge Port: Rotterdam, Netherlands (Winter Zone)

Step-by-Step Calculation:

- Identify Load Line Constraints:

- The most restrictive segment is Winter North Atlantic (WNA), requiring a freeboard of 9.80m.

- Using the Summer Draft as a reference: Summer Draft – (WNA Freeboard – Summer Freeboard) = 14.0m – (9.80m – 9.20m) = 13.40m

- The vessel must maintain a maximum draft of 13.40m before entering WNA.

- Bunker Consumption Impact:

- The vessel departs with 1,500 MT of bunker fuel, consuming 500 MT before reaching WNA.

- By adjusting for bunker depletion, the vessel’s draft can be optimized to safely navigate restrictions.

Case Study: Voyage Optimization from the US Gulf to Europe

A Panamax bulk carrier (DWT: 82,000 MT) was chartered for a grain shipment from New Orleans, USA, to Antwerp, Belgium.

Initial Plan:

- The vessel was loaded to 14.02m draft in New Orleans (Summer Zone limit).

- The voyage included a segment through the Winter North Atlantic zone, restricting the allowable draft to 13.55m.

Load Plan Adjustments:

- The original cargo load of 66,000 MT was revised to 63,500 MT to avoid mid-voyage de-ballasting.

- Additional ballast was carried through WNA to maintain vessel stability and compliance.

- The vessel strategically bunkered at Gibraltar, allowing fuel weight to be reduced before entering WNA.

Results and Benefits:

✔ The vessel avoided delays and draft compliance issues at discharge.

✔ The optimized load plan maximized cargo intake while ensuring regulatory compliance.

✔ The charterer mitigated risks associated with re-stowage costs and draft trimming delays.

Best Practices for Voyage Loadability Optimization

- Identify the most restrictive Load Line zones and adjust cargo intake accordingly.

- Use voyage simulation tools to model different loadability scenarios for various seasonal zones.

- Plan to bunker strategically to prevent exceeding draft limits at critical voyage segments.

- Ensure stability compliance by considering ballast adjustments and fuel consumption trends.

- Monitor real-time weather conditions that may impact load line restrictions mid-voyage.

Conclusion

Optimizing vessel loadability requires a holistic approach, balancing cargo intake, fuel consumption, and regulatory compliance. By leveraging data-driven planning, bunker management strategies, and stability assessments, ship operators can maximize freight revenue, enhance operational efficiency, and ensure voyage safety.

For charterers, ship operators, and logistics planners, understanding these principles is key to achieving cost-effective and compliant voyages in today’s dynamic shipping environment.