In today’s competitive maritime industry, vessel performance has become one of the most important areas of focus for shipowners, charterers, and operators. A ship’s ability to maintain the promised speed and fuel consumption directly affects voyage costs, emissions, and even commercial relationships.

But what exactly is vessel performance? How is it evaluated? And why does it carry so much weight in modern shipping contracts?

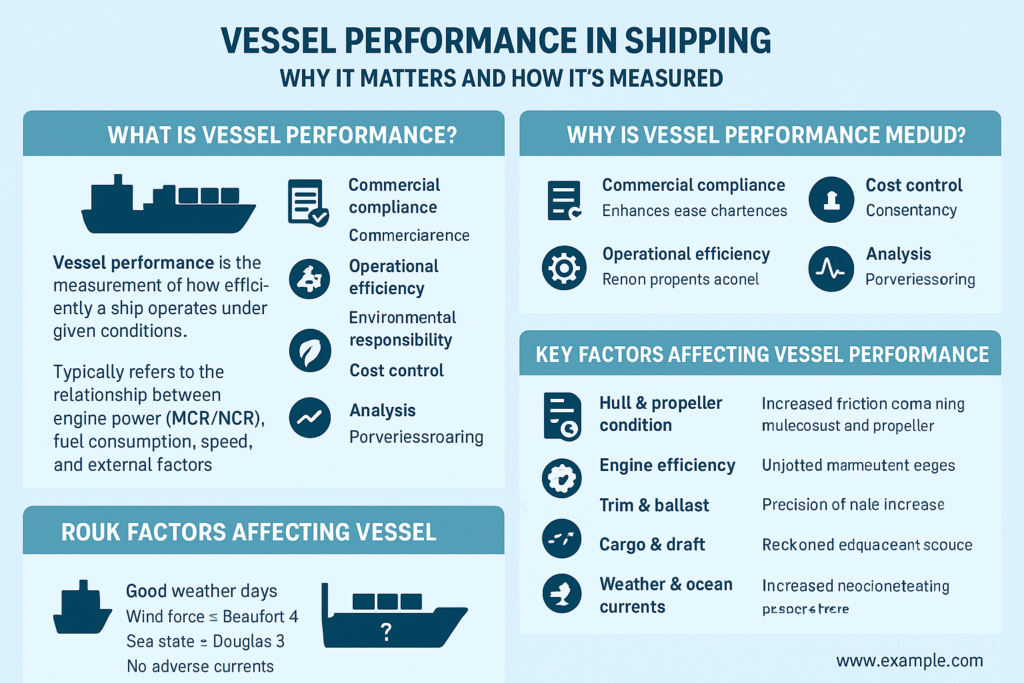

What is Vessel Performance?

Vessel performance is the measurement of how efficiently a ship operates under given conditions. It typically refers to the relationship between engine power (MCR/NCR), fuel consumption, speed, and external factors such as weather and sea conditions.

In practice, vessel performance evaluation answers a simple but critical question:

👉 “Did the ship achieve the speed and fuel consumption promised in the charter party agreement?”

Why is Vessel Performance Measured?

- Commercial Compliance

- In time charter contracts, owners guarantee certain speed and fuel consumption figures in good weather.

- If the vessel underperforms, charterers may claim for excess fuel costs or lost time.

- Operational Efficiency

- Monitoring helps identify issues like hull fouling, propeller inefficiency, or engine problems before they worsen.

- Environmental Responsibility

- With regulations like IMO’s CII and EEXI, vessels must demonstrate improved efficiency and lower emissions.

- Cost Control

- Fuel is the single biggest operating cost for ships. Even a 0.5 knot drop in speed at the same consumption can translate into huge financial losses over a long voyage.

- How is Vessel Performance Evaluated?

- Data Collection

- Daily noon reports from the ship (position, weather, speed, consumption).

- Engine load records (MCR/NCR %).

- Weather routing service reports.

- Model Comparison

- Each vessel has a speed/consumption model developed from sea trials and past data.

- Actual voyage data is compared with this model to detect deviations.

- Good Weather Filtering

- Only periods with calm seas, low wind, and no currents are considered.

- This ensures that underperformance is not blamed on external conditions.

- Analysis

- If actual performance is worse than the model under good-weather conditions, it usually points to:

- Hull fouling (marine growth increases resistance).

- Propeller inefficiency.

- Engine derating or tuning issues.

- If actual performance is worse than the model under good-weather conditions, it usually points to:

Determining if the Hull is Fouled

Hull fouling is one of the most common reasons for poor vessel performance. It occurs when marine organisms such as algae, barnacles, or slime attach themselves to the underwater parts of the ship. Over time, this increases resistance, reduces speed, and raises fuel consumption.

Signs that indicate hull fouling include:

- Speed loss at constant engine load – if the vessel cannot reach its normal speed even though the engine power remains the same.

- Increased fuel consumption per nautical mile – especially in good weather conditions.

- Prolonged stays in warm or tropical waters – these regions accelerate biofouling growth.

- Past underwater inspection reports – divers or ROV inspections often reveal marine growth on hull plates, sea chests, and propellers.

If these factors are observed, scheduling a hull cleaning and propeller polishing can restore vessel efficiency.

Key Factors Affecting Vessel Performance

- Hull & Propeller Condition – Fouling and damage increase drag.

- Engine Efficiency – Poor tuning or worn components reduce output.

- Trim & Ballast – Incorrect trim increases resistance and fuel use.

- Cargo & Draft – Heavier drafts mean more displacement and fuel burn.

- Weather & Ocean Currents – Wind, waves, and currents can significantly affect speed and consumption.

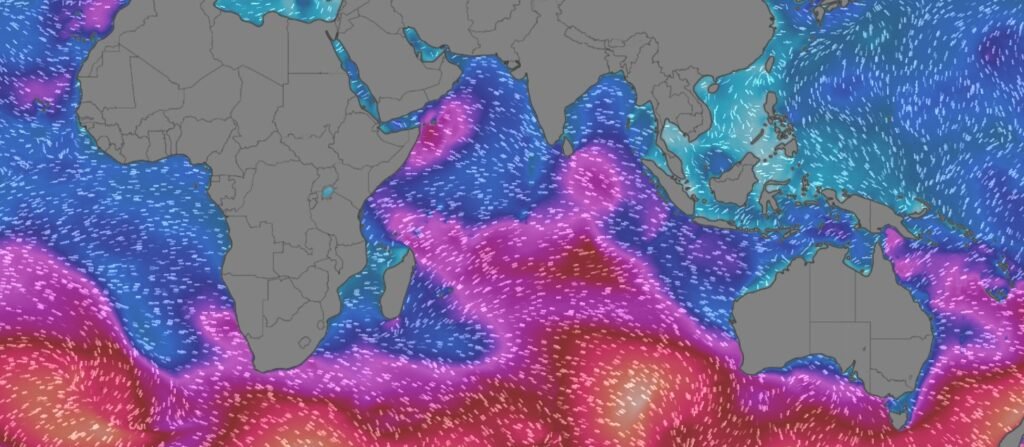

Role of Weather Forecasting

Weather plays a critical role in performance claims. To ensure fairness, vessel performance is usually evaluated under good weather days, often defined as:

- Wind force ≤ Beaufort 4

- Sea state ≤ Douglas 3

- No adverse currents

Modern performance monitoring companies use satellite weather data, hindcast models, and routing software to match actual vessel tracks with precise weather conditions. This eliminates disputes by ensuring that speed and fuel performance are compared against the agreed weather limits in the charter party.Vessel Performance Comparison Table

| Engine Load (% MCR) | Speed (knots) | Fuel Consumption (tons/day) | Fuel per Nautical Mile (tons/nm) | Operational Notes |

|---|---|---|---|---|

| 30% | ~9 | ~15 | 1.67 | Ultra-slow steaming. Risk of engine fouling, poor combustion. Not recommended unless derated. |

| 50% | ~12 | ~25 | 2.08 | Slow steaming. Fuel savings compared to NCR, but needs careful monitoring. |

| 70% | ~14 | ~40 | 2.86 | Economical range. Common for cost-saving voyages, reasonable speed. |

| 85% (NCR) | ~15.5 | ~55 | 3.55 | Optimum operating zone. Balanced between speed, fuel efficiency, and engine health. |

| 100% (MCR) | ~17 | ~75 | 4.41 | Maximum speed. High wear, very costly fuel-wise. Used only for emergencies or tight schedules. |

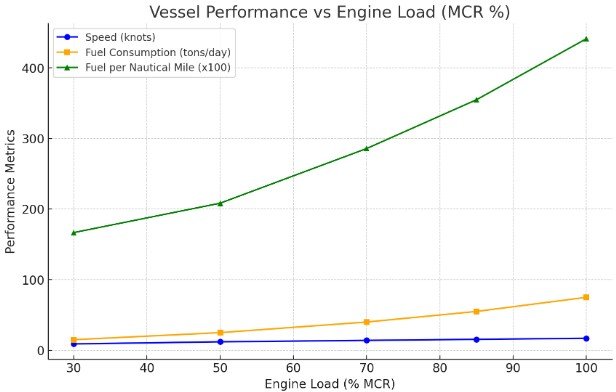

Graphical Representation

The following graph illustrates how engine load (MCR %) affects speed, fuel consumption, and fuel efficiency:

- Blue line → Ship speed increases with load.

- Orange line → Fuel consumption rises sharply at higher loads.

- Green line → Fuel efficiency (tons/nm) is best around 70–85% MCR (NCR zone).

Conclusion

Vessel performance monitoring is no longer just a reporting exercise — it is at the heart of commercial shipping. By accurately measuring speed and fuel consumption against agreed models, supported by reliable weather data, ship operators can ensure compliance, reduce costs, and maintain competitiveness in a market where efficiency is everything.

Proactive monitoring also helps detect issues like hull fouling, which, if left unaddressed, can severely impact performance and profitability. In an era of rising fuel prices and tightening emission standards, vessel performance is the key to sustainable and profitable operations.